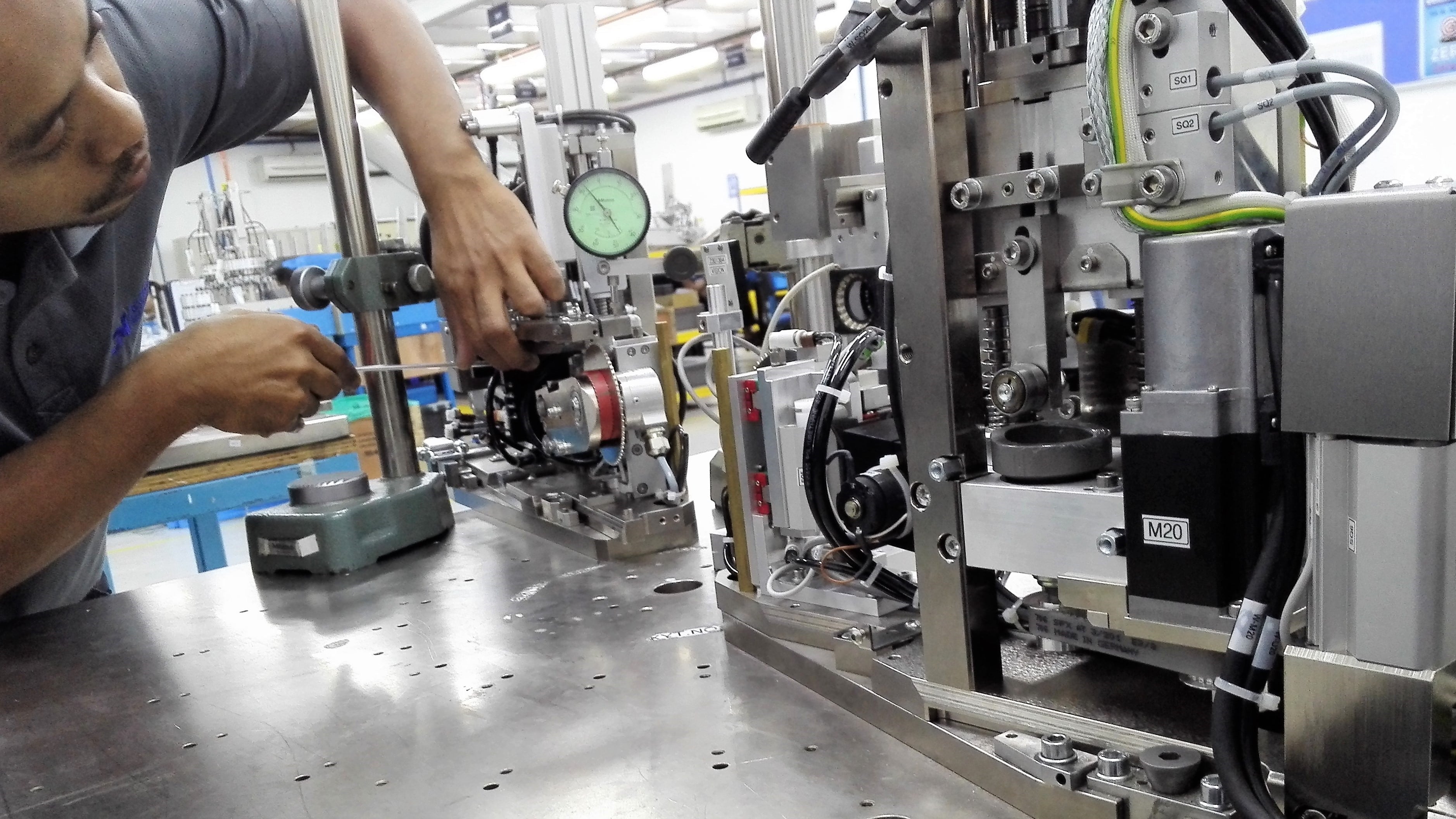

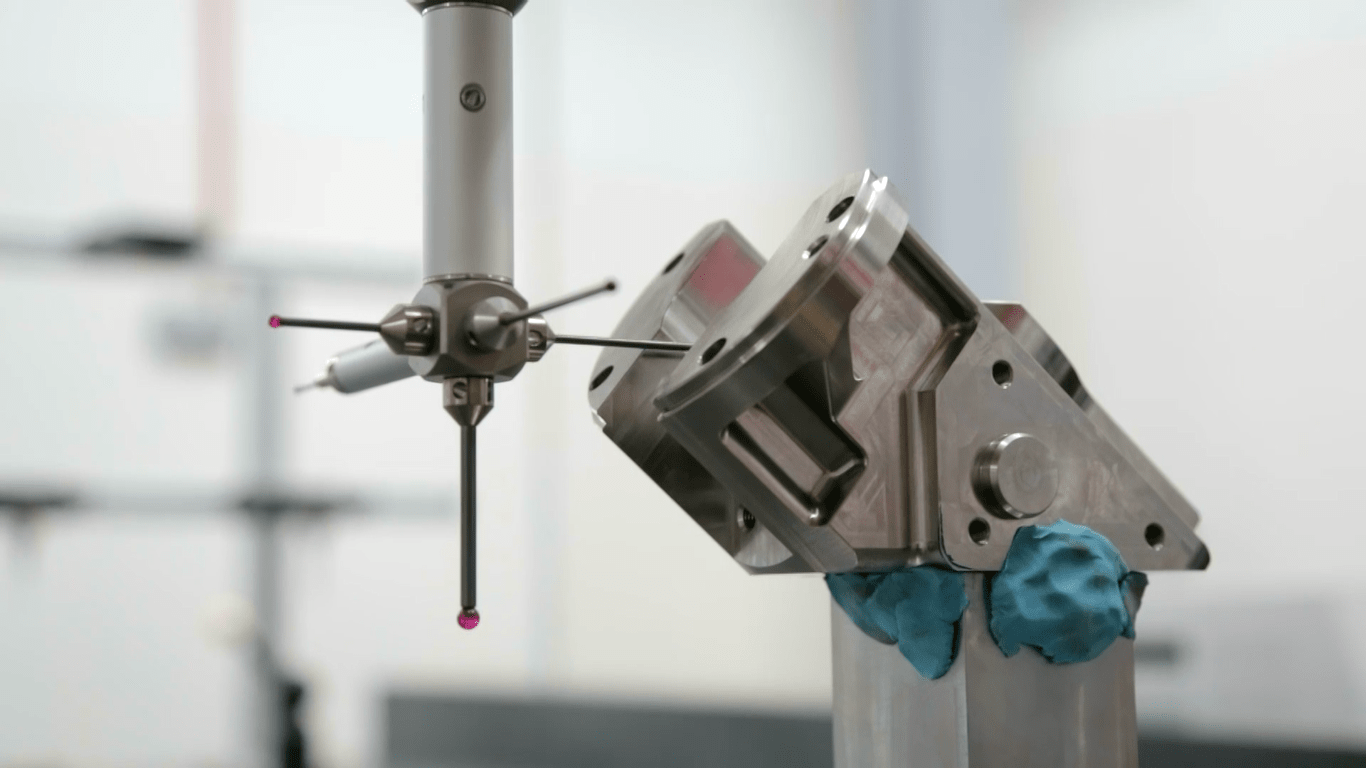

A wide range of CNC machines are installed catering high precision requirement at different sizes and batch quantities, whether it is metal or non-metal, soft or hard metal.

- 3 axis CNC vertical milling up to 2000 x 1400 mm

- 4 axis CNC vertical, horizontal milling up to 730 x 650 mm

- 5 axis CNC vertical, horizontal milling up to 6000 x 3600 mm

- 5 axis CNC multi-tasking mill-turn up to 615 x 250 mm

- 2 axis CNC horizontal lathe up to ø450 x 1500 mm

- 4 axis CNC horizontal turn-mill up to ø380 x 575 mm

- 10 axis CNC sliding head auto-lathe up to ø26 x 400 mm